Digital Twin technology is becoming a strategic tool that enables businesses to simulate, monitor, and optimize operational processes in real time. However, successfully implementing a Digital Twin requires more than just technology—it demands deep industry expertise and strong system integration capabilities.

This article will help you understand how BAP Software, a pioneer in Digital Twin implementation services, has applied this technology across industries such as manufacturing, logistics, energy, and smart factory operations through real-world case studies.

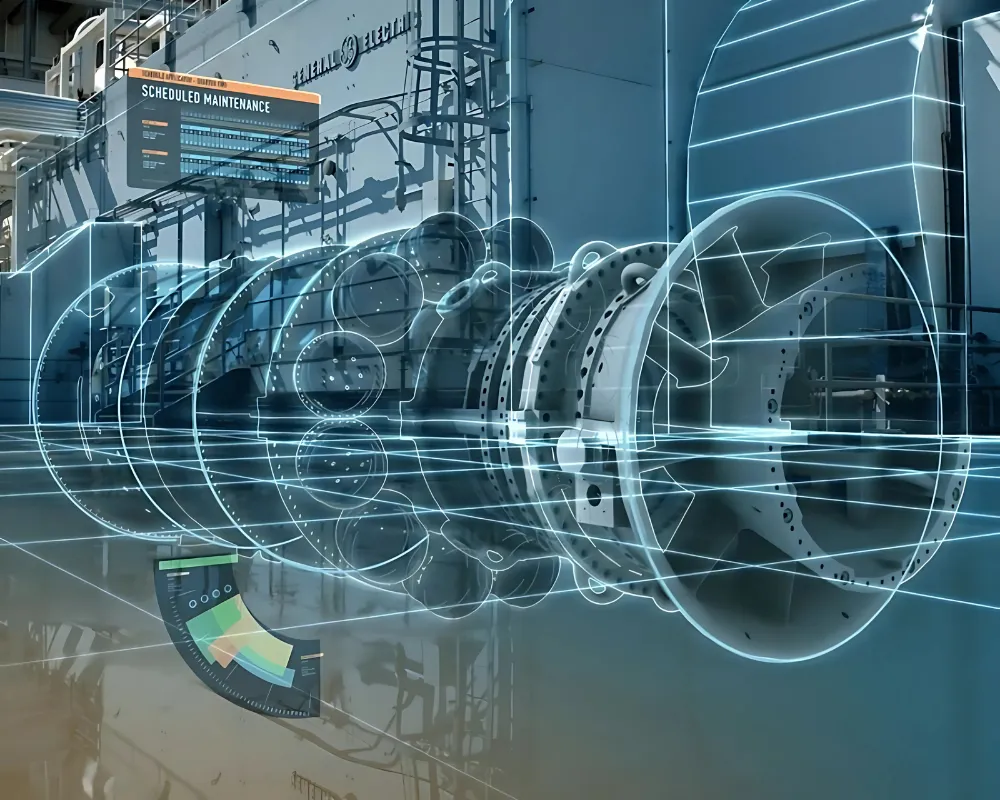

Digital Twin Deployment Services. Source: Cloudfront

1. What is a Digital Twin?

A Digital Twin is a virtual model that accurately reflects the state, behavior, and performance of a physical object, process, or system in real time.

Unlike a static 3D model, a Digital Twin is a “living replica”, continuously updating data and responding to real-world changes through the integration of IoT sensors, SCADA systems, and AI/ML technologies.

1.1. Core Characteristics of Digital Twin

Accurate simulation of physical systems: from individual devices (such as engines or machines) to entire processes (factories, operational systems, etc.).

Real-time updates: sensor data is fed into the model, continuously reflecting the operational status.

Predictive and optimization capabilities: by analyzing historical data, a Digital Twin can predict failures, optimize energy usage, or suggest operational adjustments.

According to Gartner, by 2027, over 80% of organizations with IoT initiatives will use Digital Twin technology to improve operational efficiency and make data-driven decisions.

1.2. Comparison: Digital Twin vs. Traditional Systems

| Criteria | 3D Model | IoT Platform | Digital Twin |

|---|---|---|---|

| Visual representation | ✔️ | ❌ | ✔️ |

| Real-time data connection | ❌ | ✔️ | ✔️ |

| Prediction & simulation | ❌ | ❌ | ✔️ |

| Full physical system reflection | ❌ | Partial | ✔️ |

| Human–machine interaction | Limited | Moderate | High |

Conclusion: A Digital Twin is not merely a dashboard or a visual interface — it is an analytical, predictive, and orchestration system that enables businesses to make faster and more accurate decisions.

1.3. Common Types of Digital Twin

Depending on scale and application goals, Digital Twins can be categorized into:

Product Twin: simulates the operation of specific equipment such as machines, engines, or robots.

Process Twin: models the flow of materials and data within production lines.

System Twin: connects multiple processes and devices into a comprehensive orchestration model — such as a factory, building, or entire supply chain.

1.4. Real-World Applications of Digital Twin

Smart manufacturing: monitor machine status, optimize maintenance, and reduce downtime.

Logistics & supply chain: simulate transportation flows and predict warehouse bottlenecks.

Construction & building management: control electrical, HVAC, and elevator systems to optimize operational costs.

Renewable energy: monitor solar system performance and issue fault alerts.

Healthcare: model medical equipment or patient conditions in simulated surgeries.

Overview of Digital Twin Technology. Source: Springer Nature

2. Benefits of Implementing Digital Twin for Enterprises

A Digital Twin is not just a virtual replica of a physical system — it is a strategic tool that helps businesses optimize operations, reduce risks, and accelerate innovation.

By applying Digital Twin technology in manufacturing, logistics, energy, and healthcare, organizations can enhance operational efficiency and gain comprehensive real-time control over their systems.

2.1. Optimize Operational Performance

Digital Twin enables businesses to simulate and monitor equipment, processes, or entire plants in real time.

By analyzing sensor data and predicting operational trends, companies can detect anomalies early and make timely adjustments, thereby reducing downtime and extending equipment lifespan.

2.2. Reduce Maintenance and Repair Costs

Instead of waiting for equipment to fail before performing repairs (reactive maintenance), Digital Twin enables a predictive maintenance model.

Through historical data analysis and AI insights, the system can alert operators about potential failures, helping optimize maintenance schedules and minimize unnecessary interruptions or replacement costs.

2.3. Simulate and Test Before Real Implementation

One of the greatest advantages of Digital Twin technology is its ability to simulate complex scenarios in a virtual environment.

Before investing in new production lines, processes, or system upgrades, businesses can run simulations to measure performance and identify potential bottlenecks. This approach minimizes risks and optimizes initial investment costs.

2.4. Enhance Risk Response Capabilities

In today’s volatile business environment, the ability to predict and rapidly adapt to risks is critical. Digital Twin provides a real-time monitoring layer, integrating data from various sources such as IoT sensors, ERP, and SCM systems to issue early warnings and suggest automated responses.

As a result, organizations can react faster to emergencies — from natural disasters to supply chain disruptions.

2.5. Boost Product Personalization and Development

For businesses producing customized products, Digital Twin helps simulate production processes under different configurations, enabling rapid, precise customization. Additionally, data collected from the digital model supports R&D teams in optimizing product design, shortening development cycles, and accelerating time-to-market.

2.6. Support Data-Driven Strategic Decision-Making

When integrated with data analytics systems (BI, AI, ML), Digital Twin provides intuitive dashboards, real-time reports, and actionable insights based on actual data. This empowers business leaders to make evidence-based decisions, improving accuracy and management efficiency across the organization.

Benefits of Implementing Digital Twin for Businesses. Source: SupplyOn

3. Digital Twin Implementation Process at BAP

Implementing a Digital Twin system is not merely about integrating software — it is a comprehensive transformation project requiring deep understanding of both physical systems, real-time data, and the enterprise’s operational environment.

With extensive experience across manufacturing, logistics, energy, and healthcare, BAP Software has developed a systematic and flexible implementation process tailored to each industry.

3.1. System and IoT Device Assessment

The process begins with BAP’s engineers and system experts conducting an on-site assessment of the company’s operational systems — including production lines, industrial equipment, existing IoT sensors, and data input sources.

The objectives are to identify:

Devices that need to be digitized

Real-time data transmission capability

Communication standards (Modbus, MQTT, OPC UA…) and technical limitations

Through this, BAP evaluates readiness and develops a plan to connect physical devices to the Digital Twin system.

3.2. Designing the Digital Model and Data Flows

After the assessment, BAP builds a Digital Twin model that mirrors the physical structure of the real system. The model can be in 2D, 3D, or a logical simulation depending on the intended application.

Simultaneously, data flows from sensors, edge devices, SCADA systems, or existing software are mapped and modeled. Building a standardized data model is the foundation for efficient analytics in later stages.

3.3. Integration with ERP, MES, SCADA

A Digital Twin cannot function in isolation. BAP supports integration with enterprise systems such as:

ERP (Enterprise Resource Planning)

MES (Manufacturing Execution System)

SCADA (Supervisory Control and Data Acquisition)

DMS, CRM, and other internal systems

The goal is to create a comprehensive digital replica, where all data are updated in real time and visualized on a unified platform.

3.4. Dashboard Development and Analytics

Based on business objectives (monitoring, alerting, analytics, prediction…), BAP develops an intuitive dashboard interface that integrates BI, AI, and ML analytics tools.

The dashboard can display:

Equipment performance (OEE)

Energy consumption

Real-time production flow

Parameter deviation alerts

Predictive maintenance insights

BAP leverages modern technologies such as ReactJS, NodeJS, Python, and integrates with AWS, Azure, or Google Cloud to ensure system stability and security.

3.5. User Training and System Handover

Once the Digital Twin system is completed, BAP provides on-site training for the client’s operation and IT teams. Detailed documentation, maintenance procedures, and data update workflows are delivered to ensure long-term sustainability and scalability.

BAP’s support team continues to accompany clients post-deployment, providing timely technical assistance and system expansion support as needed.

Digital Twin Implementation Process at BAP. Source: TechTarget

4. Real-world Digital Twin Case Studies at BAP

As one of the pioneering companies applying Digital Twin technology in Japan, Vietnam, and Southeast Asia, BAP Software has successfully delivered numerous projects across manufacturing, logistics, energy, and building management.

Below are selected case studies that showcase BAP’s real implementation capability and the tangible results achieved by clients.

4.1. Electronics Manufacturing Plant – Digital Twin Integrated with AI Vision

Background & Requirements:

A Japanese electronics manufacturer faced difficulties in quality control, with fluctuating defect rates on the production line, leading to material waste and delayed deliveries.

BAP’s Solution:

Built a Digital Twin to simulate the production line in real time.

Integrated an AI Vision system using high-resolution cameras and YOLO algorithms to automatically detect product defects at each stage.

Collected and analyzed data via a central dashboard connected to the MES and internal alert system.

Results:

Reduced product defects by 15% within just two months.

Saved over 10% in energy consumption by automatically optimizing machine operations upon detecting anomalies.

Enhanced QA and technical teams’ response time, minimizing downtime and ensuring stable operations.

4.2. Logistics & Warehousing – Transport Flow Simulation and Storage Optimization

Background & Requirements:

A Vietnamese logistics enterprise operating nationwide warehouses needed a solution to simulate transport activities and optimize storage for higher efficiency.

BAP’s Solution:

Developed a Digital Twin to visualize real-time cargo movement across central warehouses.

Deployed location and temperature sensors to monitor item position and condition.

Implemented AI-based heatmap analysis to predict congestion points and recommend optimized warehouse layouts.

Results:

Improved storage efficiency by 20% through intelligent arrangement by product type.

Reduced order processing time by 18% thanks to optimized transport flow.

Lowered inventory misplacement errors to below 2%.

4.3. Smart Building – Digital Twin for Energy Monitoring

Background & Requirements:

A real estate company managing multiple office buildings in Ho Chi Minh City sought to establish a centralized system for energy monitoring and automated incident alerts.

BAP’s Solution:

Developed a Digital Twin to simulate the entire building system (HVAC, elevators, lighting, etc.).

Integrated with existing IoT systems to collect energy usage data per zone.

Built an AI-based alert mechanism to detect abnormal consumption and recommend corrective actions.

Results:

Achieved an average 12% reduction in monthly electricity costs.

Early detection of HVAC malfunctions on two floors prevented electrical overload risks.

Improved green operation index, helping the building achieve LEED Silver certification.

4.4. Renewable Energy Plant – Digital Twin for Solar Power Systems

Background & Requirements:

A solar power plant in Ninh Thuan required a comprehensive simulation system to monitor panel performance and forecast output based on weather conditions.

BAP’s Solution:

Built a Digital Twin of the entire solar farm, integrating panel maps, tilt angles, and environmental sensors.

Enabled real-time output forecasting using weather API data combined with AI analytics.

Implemented alerts for underperforming, damaged, or unstable panels.

Results:

Achieved 95% accuracy in electricity output forecasts.

Detected and replaced 3% of faulty panels, preventing losses worth hundreds of millions of VND annually.

Improved maintenance scheduling efficiency by 30%.

Real-world Digital Twin Case Studies at BAP. Source: ASME

5. Why Choose BAP as Your Digital Twin Implementation Partner?

BAP Software is more than just a software development company — we are a strategic technology partner helping enterprises achieve full-scale digitalization. Our proven capabilities in Digital Twin implementation aligned with global standards make us a trusted partner for businesses across Japan, Singapore, and Vietnam.

5.1. Proven Multi-National Experience

BAP has successfully implemented Digital Twin systems across industries such as manufacturing, renewable energy, logistics, and building management in Japan, Singapore, Korea, and Vietnam.

Each project is customized to match the specific operations and local business requirements, ensuring practical impact rather than just a virtual model.

5.2. Cross-Disciplinary Engineering Team

BAP’s strength lies in its team of experts spanning all core components of a complete Digital Twin system:

IoT Engineers – integrating sensors and physical control systems

AI Engineers – handling big data and performance prediction

Big Data & Backend Specialists – designing real-time data architectures

Industrial System Engineers – understanding operational needs across sectors

5.3. Secure & Structured Implementation Process

All projects are executed under Agile and DevOps methodologies, ensuring flexibility and continuous improvement through real-time feedback.

BAP adheres to ISO/IEC 27001 security standards, guaranteeing robust data protection and compliance — a critical factor when connecting physical systems with digital platforms.

5.4. Diverse Infrastructure & Technology Stack

BAP masters a broad range of core technologies for Digital Twin development:

Unity / Unreal Engine – for 3D modeling and interactive visualization

Siemens Digital Industries Software – for production system and SCADA integration

AWS IoT Core / Azure Digital Twins – for real-time sensor data collection and processing

Grafana / Power BI – for dashboard visualization and performance analytics

This multi-platform expertise allows BAP to deliver fully customized, scalable solutions without being tied to a single vendor, ensuring long-term flexibility and cost efficiency.

Why Choose BAP as Your Digital Twin Implementation Partner. Source: Gear Technology India

6. Conclusion

In the era of Industry 4.0, Digital Twin is no longer a distant concept — it has become a strategic tool for enterprises to optimize operations, predict risks, and enhance real-time performance.

Beyond allowing businesses to see how their systems operate in the digital space, Digital Twin helps them understand — and ultimately optimize — every process and value chain in their organization.

Choosing the right Digital Twin implementation partner can save months of trial and error, reduce waste, and enable seamless scalability in the future.

If you are seeking a smart, sustainable, and scalable solution for your digital operation transformation, BAP Software is ready to accompany you from consulting and design to full-scale implementation.

Contact BAP Software today to begin your Digital Twin journey — tailored precisely to your business model.