In the era of data explosion, manufacturing enterprises and smart cities require data processing solutions that are faster, more secure, and more accurate than ever before. Edge Computing—data processing at the source—combined with Digital Twin—a digital model that simulates real-world systems—is emerging as a strategic technology duo. Together, they enable operational optimization, fault prediction, and enhanced service quality. This combination is a key enabler for entering the era of intelligent manufacturing and modern urban management.

1. Technology Context & Trends

1.1 The Data-Driven Digital Era

In the digital era, the volume of data generated by billions of IoT sensors, AI-powered cameras, mobile devices, and industrial systems is growing at an unprecedented rate. In manufacturing and smart city domains alone, data is continuously collected from production lines, traffic systems, power grids, water management infrastructures, and numerous other applications.

1.2 Limitations of the Traditional Cloud-Only Model

However, traditional centralized data processing models (cloud-only architectures) are increasingly exposing critical limitations:

High latency due to data transmission from devices → cloud → devices.

Significant bandwidth costs when continuously transmitting large volumes of video, image, and sensor data.

Security risks arising when sensitive data leaves the local or on-premise environment.

1.3 Edge Computing as a Core Enabler

As a result, Edge Computing—the technology that processes data directly at or near the data source—has emerged as a core solution to:

Reduce latency

Optimize bandwidth utilization

Enhance data security and privacy

1.4 The Power of Combining Edge Computing with Digital Twin

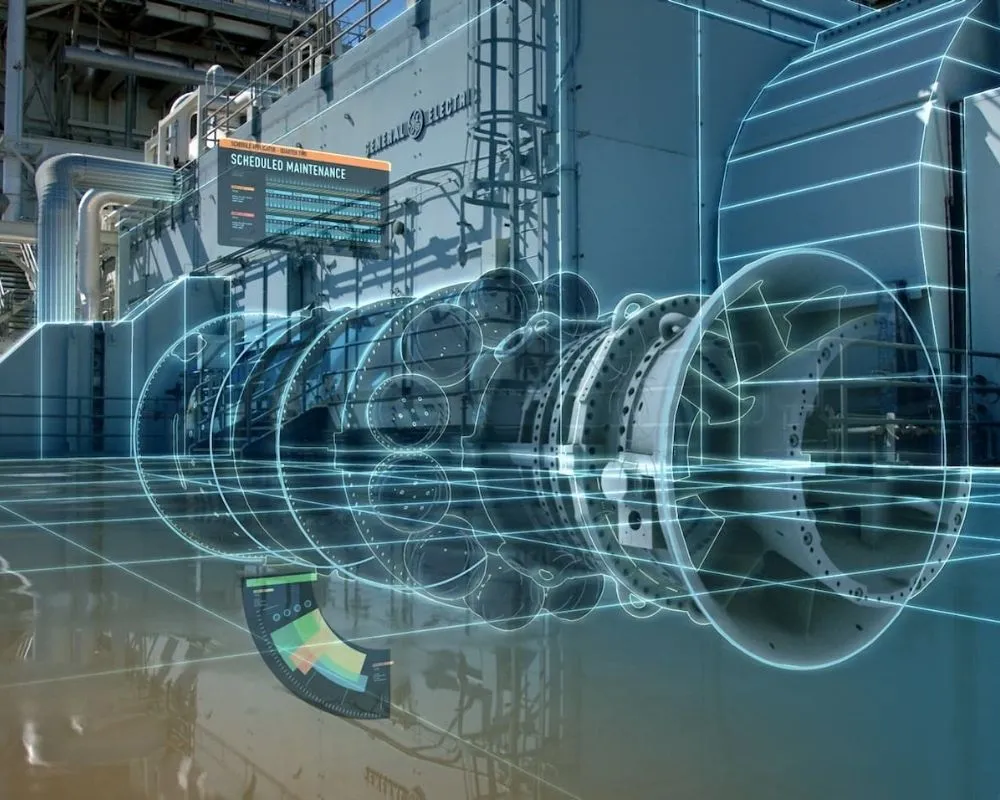

When integrated with Digital Twin—a digital replica that accurately represents the state, behavior, and performance of a physical system—enterprises and city authorities can:

Monitor, predict, and optimize operations in real time

Make faster, data-driven decisions based on instant insights and accurate simulations

Improve failure prediction capabilities and proactively address issues before they occur

1.5 Global Adoption Trends

This technology trend is being rapidly adopted in advanced manufacturing facilities and smart cities across Japan, Singapore, and Europe, and is expected to become a global standard within the next 3–5 years.

Market Landscape Overview. Source: Triaxtec

7. Edge Computing & Digital Twin Services by BAP Software

BAP Software delivers end-to-end Edge Computing and Digital Twin solutions, built on deep technical expertise, hands-on implementation experience, and in-depth knowledge of industrial and manufacturing systems.

7.1 Core Technology Capabilities

- IoT & Edge Gateways – The Foundation for Real-Time Data

BAP has extensive experience in deploying sensors, gateways, and IoT infrastructure, enabling data collection and processing directly at the edge. This is a critical foundation for building stable, accurate, and scalable edge solutions.

- AI, Computer Vision & Machine Learning at the Edge

BAP’s engineering team develops specialized AI modules such as computer vision, time-series analytics, and anomaly detection, deployable directly on edge devices or synchronized with Digital Twin models to support prediction, alerting, and preventive actions.

- Big Data & Cloud – Integrated Edge–Cloud Architecture

BAP designs optimized Edge–Cloud hybrid architectures, ensuring fast local processing at the edge while enabling advanced analytics on cloud platforms for reporting, long-term analysis, and data-driven operational optimization.

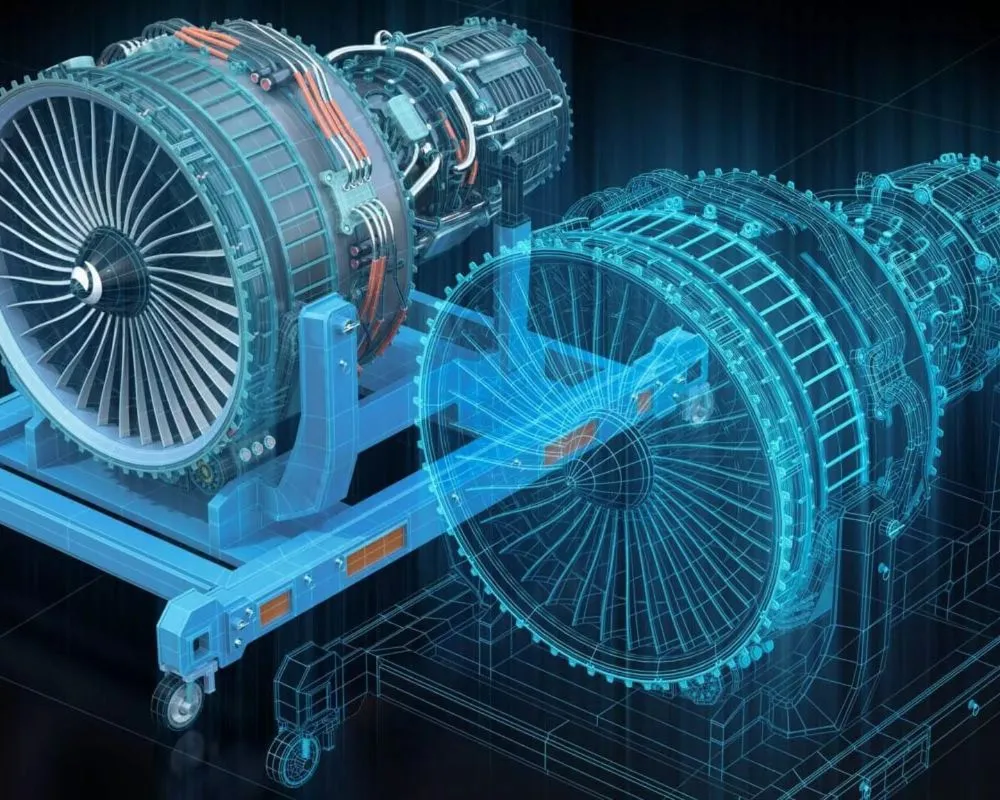

- 3D Simulation, Digital Twin & AR/VR

BAP builds Digital Twin models with 3D simulation, real-time data visualization, and live synchronization. These solutions enable enterprises to monitor the full operational lifecycle, test scenarios, and make more accurate decisions.

- Industrial System Integration (SCADA / PLC / MES / ERP / WMS)

With strong experience in integrating and optimizing industrial systems, BAP ensures seamless data flow from physical operations into digital models, creating a bi-directional feedback loop between physical systems and Digital Twins.

BAP’s Smart Factory projects clearly demonstrate this capability.

7.2 Deployment Services (From Consulting to Operations)

BAP provides end-to-end services for Edge + Digital Twin solutions, typically structured as follows:

- Assessment & Digital Audit

Evaluate existing infrastructure (sensors, PLCs, networks), determine edge node placement, assess data quality, and identify security risks.

- Architecture Design (Edge ↔ Cloud ↔ Digital Twin)

Design data processing layers (what runs at the edge vs. the cloud), select edge gateways/servers, and define Digital Twin models (3D and simulation-based).

- Rapid PoC / Proof of Concept (4–8 Weeks)

Implement small-scale pilots (e.g., anomaly detection for a single machine or a Digital Twin of one production cell) to measure performance and ROI before scaling.

BAP’s Smart Factory cases demonstrate rapid PoC execution.

- Development & Integration

Build edge agents (data ingestion, preprocessing), inference models (on-device or at-edge), Digital Twin APIs, and monitoring dashboards. Integrate with ERP, MES, and SCADA to enable automated feedback loops.

- MLOps Deployment & Operations (Monitoring, Model Retraining)

Establish CI/CD pipelines for ML, monitor model drift, enable alerting, and maintain audit logs. BAP highlights automated deployment (CI/CD) and DevOps processes in its corporate profile.

- Security & Compliance

Apply security policies, edge-level data encryption, key management, access control, and audit logging in compliance with ISO 27001, a certification that BAP holds and maintains.

- Training & Knowledge Transfer

Provide operational training, maintenance guidance, and comprehensive documentation, enabling clients to self-operate or collaborate with BAP under defined SLA agreements.

7.3 Standardized Delivery Process (Agile + DevOps + Security)

BAP follows an Agile delivery model to shorten feedback cycles, integrates DevOps / CI-CD for automated deployment, and applies ISO 27001 standards for information security.

Official company documentation highlights Scaled Agile practices, automated deployment (AWS CodePipeline, Azure DevOps), and a strong commitment to security compliance.

This ensures: rapid PoC → sprint-based scaling → stable operations with proven monitoring pipelines and security controls.

Standardized Deployment Process with BAP. Source: Roimaint

7.4 Real-World Case Studies

Below are selected real-world examples published by BAP, demonstrating how Edge + AI + Digital Twin / analytics create measurable value:

Smart Factory Agent – AI-Driven Factory Operations (Downtime Reduction)

Context: Real-time anomaly detection from cameras and sensors to reduce machine downtime.

Solution: Computer Vision (YOLOv8, OpenCV) + edge inference + notification system (bots) + private LLM for contextual analysis.

Result: ~30% downtime reduction (4-week PoC before scaling).

AI in Manufacturing – Preventing Unplanned Downtime

Context: Reduce emergency maintenance costs and improve OEE.

Solution: Sensor data ingestion → edge-based time-series models (ARIMA / LSTM) + centralized analytics; Digital Twin for scenario simulation.

Reported Results: Up to 70% reduction in unplanned downtime and ~15% OEE improvement in selected deployments.

Digital Twin & Metaverse / B2B Metaverse Platform

Context: Enterprises require 3D environments for operational simulation, training, and events at lower cost.

Solution: Metaverse-as-a-Service (cross-platform) integrated with analytics and real-time interaction.

Impact: Up to ~50% reduction in event and training costs in documented cases.

Clients can refer to BAP’s official case study pages for detailed technical validation across AI, Smart Factory, and Digital Twin projects.

7.5 Why Choose BAP for Edge + Digital Twin Implementation?

Multi-Market Implementation Experience: BAP has delivered projects across Japan, Singapore, and Vietnam, ensuring compliance with diverse regulatory, technical, and operational standards.

Security & Governance Standards: BAP holds ISO 27001 certification, a critical requirement for manufacturing data and smart city infrastructure.

True End-to-End Services: From DX consulting and architecture design to PoC, MLOps, and DevOps operations—significantly reducing time-to-value.

Why Choose BAP for Edge Computing & Digital Twin Deployment.

8. Conclusion

The convergence of Edge Computing and Digital Twin is not merely a trend—it is becoming a core foundation for smart manufacturing and smart cities. When data is processed at the source and reflected in real time within digital models, enterprises and public authorities can make faster, more accurate decisions while minimizing risk.

Early adoption enables organizations to optimize operations, reduce long-term costs, and stay ahead of emerging global standards.

Contact BAP Software today to receive expert consulting and deploy an Edge Computing & Digital Twin solution tailored to your business model.

![[ERP Comparision] – Top 5 ERP consulting companies in Japan](https://cdn.bap-software.net/2020/08/erp-comparison.jpg)