Digital Twin – real-time digital simulation technology – is becoming a vital piece in enterprises’ digital transformation journey. This article compiles the list of the Top Trusted Digital Twin Technology Companies in 2025, selected based on multiple criteria. The list serves as a valuable reference to help businesses choose the right partner for their digital transformation.

Leading Digital Twin Technology Companies. Source: CMconsulting

I. What is Digital Twin and Why is it Becoming a Trend?

Digital Twin is an advanced technology that creates a digital model of a physical object, system, or process – with the ability to simulate, monitor, and analyze the behavior of its “physical counterpart” in real time.

Unlike traditional static 3D models, Digital Twin continuously collects data from sensors, IoT systems, and management software (ERP, MES), integrated with Artificial Intelligence (AI), to accurately replicate the status and performance of real-world systems.

1. How Digital Twin Works

Real-time data collection: From physical sensors, IoT systems, SCADA, ERP, MES, etc.

Synchronization & digital simulation: Data is processed and fed into a virtual simulation model on Cloud or On-premise platforms.

Monitoring & forecasting: This digital model allows businesses to monitor current status, detect issues, and predict future trends.

Operational optimization: Businesses make strategic decisions based on insights and analytics from the Digital Twin.

2. Why Digital Twin is Becoming a Global Trend

With the rapid advancement of IoT, Big Data, AI, and Cloud technologies, Digital Twin is no longer limited to “industry giants” – it is now increasingly accessible to small and medium-sized enterprises across multiple sectors.

Key reasons why businesses are investing in Digital Twin include:

Operational optimization: Simulate entire production or operational processes to identify bottlenecks, waste, and improve efficiency.

Predictive maintenance – cost reduction: Analyze machine data to forecast maintenance schedules, preventing unexpected breakdowns.

Reduced risks in testing: Experiment with changes in processes, designs, or operating models in the simulation before applying them in reality.

Accelerating digital transformation: Digital Twin bridges the gap between the physical world and digital data – enabling smarter and more proactive decision-making.

Enhanced customer experience: Applications in retail, real estate, and smart cities allow for space and user behavior simulation, making services more tailored and effective.

3. Key Industries Applying Digital Twin

| Industry | Digital Twin Applications |

|---|---|

| Manufacturing | Production line simulation, machine monitoring, fault prediction, process improvement |

| Construction & Real Estate | Smart building management, architectural/engineering/energy simulation |

| Logistics & Supply Chain | Warehouse optimization, supply chain modeling, transportation route simulation |

| Energy | Grid monitoring, power plant predictive maintenance, smart operations |

| Healthcare | Patient simulation, smart medical devices, optimized care processes |

| Automotive & Transportation | Vehicle design testing, driver behavior simulation, maintenance optimization |

In today’s era where “data rules the game,” Digital Twin is the key technology enabling businesses to capture real operational data, predict the future, and make intelligent decisions – thereby accelerating competitiveness in the market.

Essential information about Digital Twin. Source: Topdev

II. Criteria for Selecting a Digital Twin Technology Development Company

Choosing the right technology partner plays a pivotal role in building and deploying an effective Digital Twin solution. Below are the key criteria that help businesses evaluate and select a suitable Digital Twin development company:

1. Practical Experience in Implementing Digital Twin

A reputable company must have hands-on experience in executing real Digital Twin projects, particularly in industries such as manufacturing, construction, logistics, or energy. Experience enables them to fully understand operational processes, data requirements, and system integration capabilities.

Tip: Ask the partner to provide case studies, client references, or demo projects they have implemented with Digital Twin.

2. Technological Capabilities and Professional Team

Digital Twin technology requires expertise in real-time data processing, IoT integration, AI, 3D simulation and advanced analytics. Therefore, a professional Digital Twin development company should have a team of highly skilled engineers specializing in:

AI & Machine Learning

IoT systems and sensor engineering

Digital simulation and 3D modeling

Backend and frontend software engineering

3. Integration Capability with Existing Systems

An effective Digital Twin system must seamlessly connect with platforms such as ERP, SCADA, Manufacturing Execution Systems (MES), CRM, or Business Intelligence (BI). Therefore, the chosen company should possess strong expertise in integrating complex systems using APIs or middleware platforms.

4. Customizable and Scalable Solutions

There is no “one-size-fits-all” Digital Twin solution. Evaluation criteria should include the ability to customize solutions based on real-world business requirements and to provide scalability for future growth. A good company will help you start with a small-scale Proof of Concept (PoC) and expand to cover the entire operational process.

5. Security and Compliance Standards

Since Digital Twin involves sensitive operational data, partners must ensure strict data protection and comply with international standards such as ISO/IEC 27001, GDPR, SOC 2, and others.

Criteria for selecting a Digital Twin development company. Source: Zeiss

III. Top 10 Trusted Digital Twin Technology Companies in 2025

The following list highlights the leading technology companies in Digital Twin solution development. These companies are evaluated based on their technological capabilities, implementation experience, solution customization, and customer satisfaction.

1. BAP Software (Vietnam – Japan)

Website: https://bap-software.net

Overview:

One of Vietnam’s leading technology companies with strong expertise in AI, IoT, and customized software solutions. BAP is rapidly advancing in Digital Twin, particularly in manufacturing, logistics, and industrial real estate.

Key Solutions:

Integrating IoT data into digital models of production lines.

Combining AI + Computer Vision for real-time operational monitoring.

Developing 3D interactive interfaces to simulate physical systems.

Notable Projects:

Digital Twin solution for a factory in Japan to simulate the entire production line and analyze real-time errors.

Smart warehouse monitoring system using sensor data + digital models to predict storage risks.

Strengths: Tailored customization for each industry, competitive pricing, and a team of internationally experienced engineers.

BAP – one of the trusted Digital Twin developers in Vietnam. Source: BAP Software

2. Siemens Digital Industries Software (Germany)

Website: https://www.sw.siemens.com

Overview:

Siemens is a pioneer in developing comprehensive Digital Twin solutions for industries. Their Xcelerator platform not only simulates products and operational processes but also integrates Product Lifecycle Management (PLM) for analysis and optimization.

Highlights:

Supports design, simulation, manufacturing, and supply chain management.

Integrates real IoT data from industrial equipment into virtual models.

Enables manufacturers to analyze performance and test processes in a digital environment before real-world deployment.

Real-world Applications:

Widely used in automotive, aerospace, and industrial machinery manufacturing.

Provides digital factory simulation and automated production lines.

3. General Electric – GE Digital (USA)

Website: https://www.ge.com/digital

Overview:

GE Digital, the technology arm of General Electric, delivers Digital Twin solutions through its Predix platform. They focus on creating digital twins for heavy industrial equipment, enabling monitoring, predictive maintenance, and operational optimization.

Highlights:

Equipment-level Digital Twin: simulating turbines, jet engines, etc.

Integrates sensor data and AI analytics for predictive maintenance.

Enhances reliability and reduces operational costs in energy, oil & gas, and aviation industries.

Real-world Applications:

Energy companies use GE’s Digital Twins to monitor wind turbine performance.

Aviation sector leverages Digital Twin models for jet engine predictive maintenance.

GE Digital – a leading Digital Twin provider in the USA. Source: Thanh Niên

4. Dassault Systèmes (France)

Website: https://www.3ds.com

Overview:

Famous for its 3DEXPERIENCE software, Dassault Systèmes delivers Digital Twin solutions tailored to industries requiring complex simulations such as aerospace, healthcare, and high-tech manufacturing.

Highlights:

Combines 3D CAD modeling, physics simulation, and real-world operational data.

Enables engineers to test designs before production.

Supports PLM with integrated sensor-based analytics.

Real-world Applications:

In medical devices, Digital Twin is used to simulate durability and functionality before market launch.

In construction, virtual models help optimize structures and forecast long-term maintenance costs.

5. Microsoft Azure Digital Twins (USA)

Website: Azure Digital Twins

Overview:

Part of the Microsoft Azure ecosystem, Azure Digital Twins is a platform for creating digital replicas of physical environments, enabling businesses to connect IoT data, simulate operations, and optimize processes.

Highlights:

Models relationships between devices, spaces, and people in real time.

Seamlessly integrates with Azure IoT Hub, Azure AI, Power BI, and Dynamics 365.

Applicable for Smart Buildings, Smart Factories, and energy management.

Real-world Applications:

Smart buildings monitor energy usage, security, and indoor environment in real time.

In logistics, warehouse operations are digitized to optimize storage and delivery schedules.

Microsoft Azure – Digital Twin platform within Microsoft’s ecosystem. Source: Azure

6. PTC – ThingWorx (USA)

Website: https://www.ptc.com/en/products/thingworx

Overview: PTC’s ThingWorx platform specializes in industrial IoT and Digital Twin development. It is a low-code platform that allows businesses to rapidly create digital models and integrate them with existing operations.

Highlights:

Strong integration with PTC’s CAD and PLM tools like Creo and Windchill.

Enables digital equipment modeling, real-time monitoring, and fault alerts.

Supports building custom applications with minimal coding.

Real-world Applications:

Manufacturers use ThingWorx dashboards to monitor machine performance.

Predictive failure detection in production lines via sensor data and digital modeling.

7. IBM Digital Twin Exchange (USA)

Website: https://www.ibm.com/products/digital-twin-exchange

Overview: IBM leverages data analytics, Watson AI, and IoT sensor data to deliver a robust Digital Twin platform. Their focus is on predictive maintenance, asset performance, and energy efficiency.

Highlights:

Deep integration with IBM Maximo (asset management platform).

Automates maintenance workflows using AI-driven lifecycle analytics.

Models buildings, factories, and complex engineering systems.

Real-world Applications:

In real estate, IBM helps model buildings and optimize operating costs.

In heavy industry, Digital Twins manage equipment remotely and enable smart maintenance planning.

8. Bosch.IO (Germany)

Website: Bosch.IO Digital Twin

Overview: Bosch.IO, the technology subsidiary of Bosch, focuses on connecting sensors, IoT devices, and control software to create digital models of physical systems.

Highlights:

Strong integration of physical sensors with AI models.

Tailored solutions for automotive, industrial manufacturing, and logistics.

Emphasis on environmental monitoring, risk alerts, and automated control.

Real-world Applications:

Air quality monitoring in component manufacturing plants.

Simulation of warehouse logistics flows to optimize storage layouts.

Bosch.IO – part of Bosch Group, specializing in sensor-driven solutions. Source: HLZ

9. Oracle Digital Twin (USA)

Website: https://www.oracle.com

Overview:

Oracle integrates Digital Twin technology into its ERP and SCM solutions to help businesses simulate supply chains, manage assets, and control data flows from endpoints to accounting systems.

Highlights:

Combines AI, real-time data, and financial analytics.

Highly scalable for large enterprises.

Real-world Applications:

Retailers use digital models for demand forecasting and inventory control.

Automates order orchestration across warehouses and logistics providers.

10. Ansys (USA)

Website: https://www.ansys.com

Overview:

Ansys is a global leader in engineering simulation software. Its Digital Twin solutions focus on physics simulation, digital engineering, and product performance optimization.

Highlights:

Real-time simulation of physical factors like heat, force, and electricity.

Targeted for aerospace, electronics, and advanced engineering sectors.

Enables virtual testing before real-world production.

Real-world Applications:

Aerospace companies use Ansys Digital Twins to test jet engine designs.

Electronics firms apply simulations to evaluate heat resistance and vibration tolerance.

Ansys – one of the world’s leading software companies in digital engineering simulation. Source: iltech

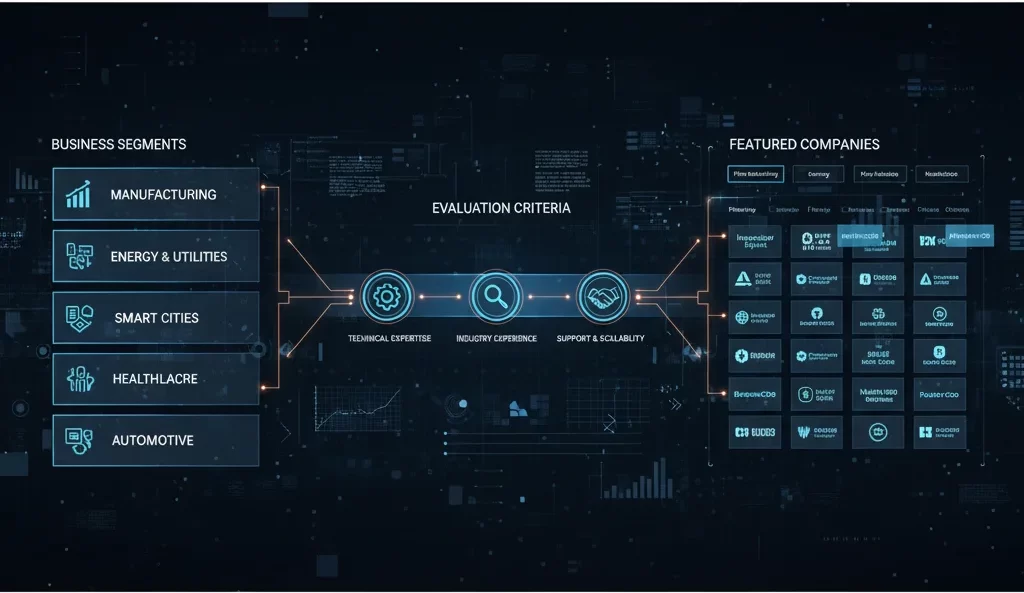

IV. Comparison & Selection of Digital Twin Companies for Different Types of Businesses

Not all Digital Twin technology providers are the same. Depending on the industry, scale, and application goals, businesses should choose the right partner to optimize investment efficiency. Below is a detailed analysis:

1. Large-scale Manufacturing Enterprises (manufacturing, industrial automation)

Specific Requirements:

Simulation of production lines, equipment, and factories.

Analysis of data from thousands of IoT sensors.

Predictive maintenance and 24/7 operational monitoring.

Recommended Companies:

Siemens Digital Industries – Specialized in smart factories and industrial systems.

GE Digital – Optimizes equipment performance and provides effective predictive maintenance.

Bosch.IO – Strong in hardware-software integration, suitable for enterprises using extensive field equipment.

2. High-tech Enterprises, Product Design (aerospace, automotive, electronics)

Specific Requirements:

Accurate physical simulations (heat, pressure, durability, etc.).

Design, testing, and optimization of products before actual production.

Recommended Companies:

Ansys – Strong in detailed physical engineering simulations.

Dassault Systèmes – Integrates 3D modeling, design, and product lifecycle management.

PTC ThingWorx – Combines CAD + IoT + operational modeling to track product status post-sales.

3. Service, Real Estate, and Commercial Enterprises

Specific Requirements:

Simulation of spaces, building systems, people flow, HVAC, and energy consumption.

Building operation management, energy optimization, and periodic maintenance.

Recommended Companies:

Microsoft Azure Digital Twins – Ideal for smart buildings, offices, and campuses.

IBM Digital Twin Exchange – Integrates asset management, energy efficiency, and technical fault prediction.

Oracle – Multi-layer data management integrated with ERP and financial systems.

4. Enterprises Seeking Customized or Rapid Deployment Solutions

Specific Requirements:

Deep customization tailored to business processes.

End-to-end consulting, flexible development, and operational support.

Recommended Companies:

BAP Software – Provides customized Digital Twin development services, integrating AI, IoT, and existing ERP/CRM systems.

Advantages: Flexible deployment (offshore/onsite), cost-effective, and cross-industry business expertise.Kore.ai / Yellow.ai – Suitable for simple, rapidly deployable solutions via low-code platforms.

5. Enterprises Looking to Integrate Digital Twin with AI, LLM, or Real-time Data

Specific Requirements:

Simulation not only of equipment but also of behaviors, operational logic, and automated decision-making.

Recommended Companies:

BAP Software – Integrates Digital Twin with AI Vision, LLM, and recommendation systems to optimize operations and user experience.

Microsoft Azure / GE Digital – Strong cloud and AI platforms for rapid integration of data and models.

Summary of Choices by Industry

| Industry / Requirements | Recommended Companies |

|---|---|

| Industrial Manufacturing | Siemens, GE Digital, Bosch.IO |

| Aerospace, Automotive, Technical Design | Ansys, Dassault Systèmes, PTC |

| Real Estate, Buildings, Service Operations | Microsoft, IBM, Oracle |

| Customized, Flexible Solutions | BAP Software, Kore.ai |

| AI + Digital Twin Integration | BAP Software, Microsoft Azure |

Comparison and selection of Digital Twin development companies by business segment. Source: SCG-Des3

V. Conclusion

Digital Twin is no longer a distant concept; it is gradually becoming a fundamental technology infrastructure in the digital transformation journey of many enterprises. Simulating the physical world with digital replicas not only optimizes operations and reduces costs but also enables predictive capabilities – empowering businesses to make faster and more accurate decisions.

However, to develop an effective Digital Twin system, businesses need to choose the right technology partner—one that understands business-specific requirements and can integrate across multiple platforms, from IoT and AI to enterprise data.

Among the standout companies, BAP Software is a reliable choice for enterprises seeking customized Digital Twin solutions, rapid deployment, and cost optimization. With proven experience in Japan, the U.S., and Southeast Asia, and strong technical expertise across AI, IoT, and traditional software development, BAP delivers comprehensive and flexible solutions tailored to each industry.

👉 If your business is considering implementing Digital Twin technology or needs consultation for the right solution, contact BAP Software today. Our team of experts is ready to support you from strategy to real-world implementation.